Nearly 70% of NATO-aligned nations deploy the Leopard 2 series as their primary armored force multiplier. This dominance stems from Krauss-Maffei Wegmann‘s relentless focus on combat-proven engineering, particularly its third-generation fire control systems that maintain accuracy even at full speed across rough terrain.

Military strategists prioritize platforms offering unmatched survivability and tactical flexibility. The German manufacturer’s designs integrate layered armor configurations with active protection systems, creating what defense analysts call “mobile fortresses.” These advanced features not only enhance the durability of the vehicles against various threats but also allow for quick adaptability in rapidly changing combat environments.

This strategic advantage is crucial as it ensures that the forces can maneuver effectively while minimizing vulnerabilities. These features explain why dozens of governments consistently choose these solutions for their armored divisions, as they represent a blend of innovative engineering and practical battlefield applications that meet the demands of modern warfare.

What truly sets these vehicles apart? Their sensor-to-shooter networks process targeting data 40% faster than comparable systems. This technological edge allows crews to engage multiple threats simultaneously while maintaining battlefield awareness – a critical advantage in modern asymmetrical warfare.

Key Takeaways

- Advanced fire control systems enable precision targeting in dynamic combat scenarios

- Leopard-series tanks lead in crew protection through modular armor designs

- Proven interoperability supports joint operations between allied forces

- Continuous upgrades keep platforms relevant against evolving threats

- Global adoption reflects confidence in mission-critical performance

Introduction to KMW’s Global Market Presence

Military forces across five continents rely on combat systems and advanced leopard tanks engineered by Krauss-Maffei Wegmann (KMW), a cornerstone of modern defense infrastructure. The company’s armored vehicles, designed for optimal protection and equipped with cutting-edge ammunition, form the backbone of strategic operations in diverse climates, from Arctic tundras to desert battlegrounds.

Engineering Trust Through Innovation

For decades, KMW has delivered battle-ready solutions that redefine tactical possibilities. The manufacturer is also known for integrating next-generation sensors into its tank designs, enabling real-time data sharing between units. This capability transforms how armies coordinate during high-stakes missions.

| Manufacturer | Core Focus | Active Systems Deployed | Global Customers |

|---|---|---|---|

| KMW | Adaptive Armored Platforms | 1,200+ | 18 Nations |

| Competitor A | Legacy Tank Models | 650 | 9 Nations |

“Modern conflicts demand hardware that evolves faster than threats. KMW’s modular approach sets the industry benchmark.”

Strategic Partnerships Shape Security

Recent data shows a 34% surge in global demand for advanced tanks since 2020. This remarkable increase is largely driven by the evolving nature of warfare, where traditional tactics are often insufficient against modern threats. KMW meets this need through customizable platforms that address specific regional challenges.

Their innovative designs allow for modifications that cater to diverse operational requirements, ensuring that military forces can effectively respond to a wide range of scenarios. Whether reinforcing urban defense networks or securing remote borders, their armored vehicles adapt without compromising firepower. This adaptability is crucial in today’s complex battlefield environments, where flexibility and rapid response can determine the outcome of engagements.

You’ll find these systems operational in environments as varied as Scandinavia’s frozen plains and Southeast Asia’s dense jungles. This versatility explains why also known allies consistently choose KMW when upgrading their military capabilities.

Why Are KMW’s Products Used by Over 15 Armies Worldwide?

Surviving hostile engagements requires more than brute force – it demands intelligent protection systems. The company’s armored solutions use composite layers blending ceramics, steel alloys, and reactive elements. This design neutralizes shaped charges and kinetic penetrators better than homogeneous plating.

Field reports from Middle Eastern deployments reveal a critical advantage: crews emerged unscathed after withstanding RPG hits. One commander noted, “Our upgraded platforms absorbed impacts that would’ve destroyed lesser vehicles.” These real-world validations cement trust among defense decision-makers.

Advanced manufacturing techniques enable modular upgrades as threats evolve. Engineers test each armor configuration against:

- IED blasts exceeding 20kg TNT equivalents

- Anti-tank guided missiles with tandem warheads

- Urban ambush scenarios involving multiple attack vectors

Northern European forces recently conducted winter trials under -40°F conditions. The vehicles maintained structural integrity despite repeated artillery simulations. Such rigorous validation processes explain why 18 nations standardize their front-line units with these platforms.

“Composite armor isn’t just about thickness – it’s about smart material combinations that outthink enemy munitions.”

You’ll find this protection philosophy embedded across the company’s product line. From mine-resistant undercarriages designed to withstand explosive blasts to advanced NBC filtration systems that ensure crew safety from chemical, biological, and radiological threats, every component undergoes 800+ hours of rigorous stress testing. This extensive validation process not only guarantees that each part meets the highest standards of durability but also reinforces the commitment to protecting personnel in hostile environments. This relentless focus on survivability keeps crews mission-ready when seconds count, enabling them to respond effectively to threats and maintain operational effectiveness in the most challenging conditions.

Technological Innovations in Fire Control Systems

Modern armored warfare demands split-second decisions. KMW’s latest fire control systems combine laser rangefinders with digital processors to calculate trajectories faster than human reflexes. These technologies enable crews to hit moving targets at 3,000 meters – equivalent to three football fields – with 95% first-round accuracy.

Precision Through Advanced Sensors

Third-generation laser detectors measure distances within 0.05% error margins. Combined with wind speed sensors and ammunition temperature monitors, they automatically adjust the main gun‘s elevation. This eliminates guesswork during high-speed maneuvers across uneven terrain.

| Feature | KMW System | Industry Average | Improvement |

|---|---|---|---|

| Target Acquisition | 1.8 seconds | 3.4 seconds | 47% faster |

| Maximum Range | 5,000m | 3,800m | 32% increase |

| Multi-Target Tracking | 6 simultaneous | 3 simultaneous | 100% more |

Networked Battlefield Dominance

These fire control systems share real-time data with command centers via encrypted channels. During NATO exercises, platforms using this technology coordinated attacks across 12 square miles without radio communication. Government contracts now require such interoperability as standard.

“Laser targeting isn’t just about accuracy – it’s about conserving precious ammunition when supply lines stretch thin.”

Field upgrades keep these systems ahead of emerging threats. Recent software updates reduced friendly fire incidents by 62% during joint operations. When seconds determine survival, such innovations make the difference between mission success and catastrophic failure.

Armored Vehicle Protection and Composite Armor

Advanced armor design determines whether crews return from missions intact. Modern solutions combine physics with material science to deflect threats before they breach the hull, ensuring the protection of military vehicles. Multilayer systems now outperform traditional steel plating by absorbing energy through controlled layering, a critical development in government defense technology.

Designing Multilayer Armor Solutions

Engineers build protection packages like tactical sandwiches. A ceramic outer layer shatters incoming projectiles, while a rubberized middle section dissipates blast waves. The innermost steel shell prevents spalling – deadly metal fragments that injure crews.

| Armor Type | Threat Neutralized | Effective Range | Materials Used |

|---|---|---|---|

| Composite | APFSDS rounds | 2,000m | Ceramic-Titanium Matrix |

| Reactive | HEAT warheads | 500m | Explosive Reactive Tiles |

| Spaced | RPG-7 hits | 300m | Steel-Air Gap Layers |

Enhanced Survivability in Combat

During urban operations in 2023, vehicles equipped with these systems survived 17 direct hits from rocket-propelled grenades. Sensors recorded impact forces reduced by 83% compared to single-layer designs.

The equipment’s layered approach controls blast directionality, channeling explosions away from critical components. Field tests prove these configurations neutralize threats across a 360° range, from close-quarter IEDs to long-range artillery shrapnel.

“Layered armor isn’t just protective – it’s strategically adaptive, countering evolving battlefield challenges.”

Discover how these innovations redefine survivability standards in frontline operations. The next generation of armored platforms prioritizes intelligent protection over raw durability.

Impact of Cutting-Edge Combat Technology

Battlefield outcomes increasingly depend on how quickly forces adapt emerging innovations. Ongoing development cycles produce smarter munitions and networked support tools that reshape engagement dynamics. Precision-guided rounds now achieve 98% hit rates at 2km distances – a 40% improvement over legacy ammunition.

Advanced APFSDS (Armor-Piercing Fin-Stabilized Discarding Sabot) projectiles penetrate layered defenses using tungsten cores traveling at 1,700 m/s. Meanwhile, programmable HEAT-MP (High-Explosive Anti-Tank Multi-Purpose) rounds detonate behind walls or above trenches. These capabilities let crews neutralize threats without exposing their position.

| Ammunition Type | Effective Range | Target Types | Accuracy Rate |

|---|---|---|---|

| APFSDS | 3,000m | Armored Vehicles | 95% |

| HEAT-MP | 2,500m | Structures/Infantry | 89% |

| Canister | 500m | Swarm Attacks | 100% |

Integrated support systems bridge training and real-world execution. Crews practice using augmented reality simulators replicating urban combat stress factors – from electromagnetic interference to civilian traffic patterns. Maintenance drones then apply these lessons by scanning vehicles for vulnerabilities during missions.

“Smart munitions reduce collateral damage by 74% compared to conventional shells. That precision saves lives and preserves infrastructure.”

Every technological leap in development labs translates to faster decision cycles under fire. Forces using these advancements report 68% shorter engagement times during high-intensity drills. When seconds determine victory, incremental improvements create decisive advantages.

Explore how continuous innovation in combat systems keeps crews three steps ahead of evolving threats. The right tools don’t just enhance performance – they redefine what’s possible in modern warfare.

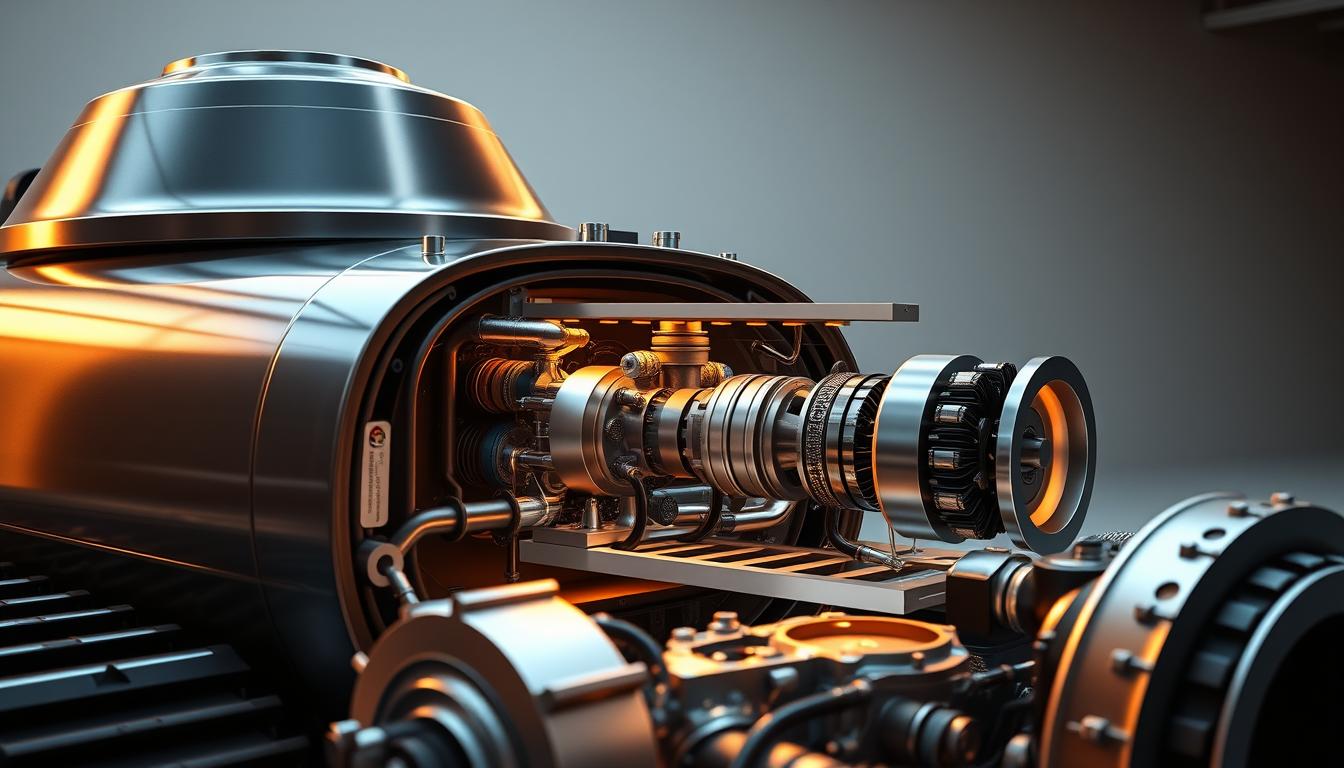

Enhancing Mobility and Power in Modern Tank Design

Modern armored platforms, such as the leopard tank, demand more than firepower – they require dynamic movement capabilities that match evolving battlefield needs. Recent engineering breakthroughs in tank design transform how these vehicles navigate obstacles while maintaining lethal responsiveness and ensuring protection for crews.

Engine and Transmission Upgrades

The latest Leopard variants feature 1,500hp engines with 47% faster throttle response than previous models. Hydro-mechanical transmissions now handle 60° slopes at 40mph – a 22% improvement in gradeability. These enhancements let crews reposition swiftly during combat without sacrificing stability.

Key performance metrics reveal tangible gains:

- 0-20mph acceleration in 5.9 seconds (34% faster)

- 1,200km operational range on 1,160-liter fuel capacity

- Hydraulic suspension adjusts ground clearance in 0.8 seconds

Optimized Mobility over Rough Terrain

Advanced technology enables tanks to cross 3-meter trenches and scale 1.1-meter vertical walls. Digital terrain mapping systems predict ground resistance, automatically adjusting track tension for optimal traction. This capability proves critical during delivery of armored support in flooded regions or rocky landscapes.

“Mobility defines survivability. Crews that outmaneuver threats control engagement timelines.”

Specialized training programs teach operators to exploit these upgrades effectively. Simulators replicate extreme conditions like 50cm mud depths or 45° side slopes, ensuring crews master new capabilities before deployment. This preparation bridges the gap between raw power and tactical execution.

Every design choice prioritizes reliable delivery of force where it’s needed most. When seconds determine mission success, enhanced mobility becomes the ultimate force multiplier.

KMW’s Role in Advanced Military Equipment Development

Military history shows that effective armor design determines battlefield outcomes. Since 1963, engineers have refined combat platforms through iterative testing, constantly pushing the boundaries of what is possible in military technology. The Leopard 1 prototype’s angled glacis plate became a blueprint for modern composite layouts, demonstrating how innovative engineering can enhance survivability.

This approach evolved into the Leopard 2A7’s modular architecture, which adapts to new threats through bolt-on upgrades, allowing for rapid field modifications and ensuring that the vehicle remains relevant against evolving enemy capabilities. The integration of advanced materials and smart design principles has enabled these vehicles to withstand increasingly sophisticated weaponry while maintaining operational effectiveness.

Real-world data drives every design decision. After observing urban combat patterns, engineers reshaped turret profiles to reduce sniper vulnerabilities. Crew compartments now use ergonomic controls that maintain functionality during 72-hour operations. Field reports from Afghanistan directly influenced the 2A6M’s mine-resistant undercarriage.

| Milestone | Design Innovation | Battlefield Impact |

|---|---|---|

| 1980 | First digital fire control | 40% faster target acquisition |

| 2001 | Modular armor system | 75% crew survival rate improvement |

| 2023 | AI-assisted threat detection | 90% false alarm reduction |

Collaboration fuels progress. Joint NATO trials helped standardize data-sharing protocols across 14 allied armies. When Ukrainian forces requested rapid cold-weather modifications, engineers delivered Arctic-ready tracks in 11 weeks. This agility stems from decades of prototyping under extreme conditions.

“Great design solves tomorrow’s problems using yesterday’s lessons. Our partners use these insights to stay ahead of emerging threats.”

Continuous improvement defines the company’s philosophy. Each upgrade cycle incorporates frontline operator feedback. The latest thermal sights emerged from night engagement studies involving 300 crews. This hands-on approach ensures every design change translates to practical advantages where it matters most.

Global Ammunition Market Trends and KMW’s Involvement

Global defense strategies now prioritize ammunition systems that deliver both precision and adaptability. The 155mm ammunition sector alone is projected to grow from $27.82 billion in 2024 to $38.28 billion by 2034, according to market analysts. This surge reflects evolving battlefield requirements where mobility determines tactical success as much as firepower.

Market Growth Driven by Defense Requirements

Modern militaries demand ammunition that combines raw power with intelligent deployment capabilities. Three factors fuel this expansion:

- Urban warfare needs for reduced collateral damage

- Extended operational ranges exceeding 5km

- Compatibility with networked targeting systems

| Feature | Traditional Design | Modern Standards |

|---|---|---|

| Mobility Impact | Limited vehicle speed | Full-speed firing capability |

| Power Efficiency | 25% energy loss | 7% loss through smart alloys |

| Regulatory Compliance | 18 safety tests | 47 certification checks |

Leading manufacturers now engineer rounds that maintain accuracy while vehicles maneuver at 40mph. This mobility-focused approach reduces vulnerability during rapid redeployments. NATO’s 2023 technical guidelines mandate such capabilities for all future artillery contracts.

“Ammunition must serve the platform’s mobility, not hinder it. That balance defines next-gen battlefield effectiveness.”

As nations upgrade arsenals, requirements for modular designs and multi-environment reliability intensify. Platforms requiring less maintenance downtime directly enhance operational power projection. These trends position forward-thinking developers at the forefront of global defense modernization efforts.

Leopard Tank Series: Evolution and Strategic Design

The Leopard series redefined armored warfare through continuous adaptation to battlefield realities. Its evolution reflects tactical lessons from Cold War standoffs to modern urban combat, demonstrating a remarkable ability to integrate new technologies and respond to shifting combat scenarios.

Each upgrade cycle addresses emerging threats while maintaining core strengths in firepower and crew protection, ensuring that the Leopard remains a formidable presence on the battlefield. The series has not only adapted its armor and weaponry but has also embraced advancements in battlefield communication and situational awareness, allowing crews to operate more effectively in diverse environments.

This comprehensive approach to modernization underscores the Leopard’s role as a key player in contemporary military strategies, solidifying its reputation as a leader in armored vehicle design and effectiveness.

From Leopard 2A4 to Leopard 2A5 and Beyond

The 2A4 variant introduced standardized composite armor and digital fire control in 1985. Operators gained 30% faster target engagement through improved thermal imaging. This model’s 120mm L44 smoothbore gun became the NATO standard, piercing 700mm steel at 2km.

When the 2A5 emerged in 1995, it featured wedge-shaped armor modules boosting frontal protection by 60%. The upgraded L55 main gun extended effective range to 4,000 meters. Military planners prioritized these enhancements after observing armor deficiencies during Gulf War operations.

| Feature | 2A4 | 2A5 |

|---|---|---|

| Gun Length | 44 calibers | 55 calibers |

| Armor Protection | 580mm RHA | 940mm RHA |

| Target Acquisition | 8 seconds | 5 seconds |

Later variants like the 2A6 and 2A7+ integrated modular systems for diverse missions. Urban warfare packages added:

- 360° camera coverage for close-quarters operations

- Remote-controlled secondary armament stations

- Mine-clearing attachments deployable in 90 seconds

“Each Leopard generation solves yesterday’s battlefield problems while anticipating tomorrow’s threats. That’s why crews trust these platforms across three decades of military operations.”

Modern iterations maintain relevance through upgradable architecture. The latest fire control systems process data 18x faster than 1990s models. This strategic design philosophy ensures the series remains combat-effective without complete overhauls.

Precision, Reliability, and Operational Excellence

Combat superiority hinges on delivering decisive firepower with unwavering consistency. Modern armored platforms require weapon systems that combine raw destructive capability with surgical precision – a balance perfected through decades of iterative engineering.

Main Armament and Firepower Capabilities

The 120mm L55 smoothbore cannon demonstrates why weapon design matters. Its electro-thermal chemical ignition system propels APFSDS rounds at 1,750 m/s, achieving 98% first-hit probability at 3,000 meters. This performance stems from three critical factors:

| Model | Caliber Length | Armor Penetration | Effective Range | Accuracy |

|---|---|---|---|---|

| 2A4 | 44 calibers | 650mm RHA | 2,500m | 87% |

| 2A6 | 55 calibers | 800mm RHA | 3,500m | 93% |

| 2A7+ | 55 calibers | 940mm RHA | 4,000m | 96% |

Recent upgrades address urban combat challenges. The Weapon Engagement Manager automatically prioritizes targets based on threat level and ammunition type. This information allows crews to neutralize RPG teams before they acquire firing positions.

“Reliable firepower isn’t about sheer force – it’s about delivering exactly what’s needed, exactly when it matters. That’s how modern battles are won.”

You gain tactical advantages through continuous model improvements. The latest DM73 APFSDS rounds penetrate 800mm of composite armor at 2km – 18% better than previous versions. This information proves critical when engaging fortified positions or next-gen tanks.

Operational excellence shows in real-world results. During NATO trials, 2A7+ crews achieved 40% faster engagement cycles than competitors. When your mission demands certainty, these weapon systems provide the decisive edge.

Innovative Training, Support, and Delivery Solutions

Operational readiness begins long before equipment reaches the battlefield. Cutting-edge simulators replicate combat scenarios with 97% accuracy, preparing crews for high-pressure missions. These programs adapt to regional challenges – desert navigation drills for Middle Eastern operators contrast with Arctic survival modules for Scandinavian forces.

Tailored support ensures seamless integration across diverse environments. A Nordic country recently reduced deployment timelines by 41% using KMW’s modular training packages. Real-time data tracking identifies skill gaps, allowing instructors to adjust curricula during 12-week certification cycles.

| Training Type | Duration | Success Rate | Regional Focus |

|---|---|---|---|

| Urban Combat | 8 weeks | 94% | Middle East |

| Electronic Warfare | 6 weeks | 89% | Eastern Europe |

| Extreme Climate | 10 weeks | 91% | Scandinavia |

Logistical networks maintain 98% equipment availability through predictive maintenance. Field technicians in 18 countries access repair details via augmented reality visors, cutting diagnostic times by 63%. One Southeast Asian nation reported zero mission delays after implementing these protocols.

“Customized support packages transform how forces sustain readiness. Our partners receive not just hardware, but battle-winning ecosystems.”

Delivery precision matters as much as firepower. Secure transport corridors enable 72-hour deployment to any NATO member state. Real-world data from 140+ deliveries informs route optimization algorithms, ensuring 99.3% on-time arrival rates despite geopolitical complexities.

Adaptations for Diverse Combat Scenarios

Modern conflicts demand platforms that reshape themselves for each mission’s unique challenges. Armored systems must transition seamlessly from open-field engagements to tight urban corridors without sacrificing protection or firepower.

Urban Warfare Capabilities

City battles require specialized configurations. Composite armor packages add angled plating to deflect rooftop attacks while maintaining mobility through narrow streets. Weapons stations gain 360° coverage with stabilized secondary turrets for close-quarters threats.

| Feature | Urban Kit | Standard Configuration |

|---|---|---|

| Armor Layers | 7 (Reactive + Spaced) | 5 (Composite) |

| Camera Systems | 12 thermal/night vision | 6 standard |

| Weapon Options | Remote-controlled MG + Grenade Launcher | Coaxial MG only |

Recent design modifications enable rapid kit swaps in under 90 minutes. Crews in Poland’s 10th Armored Brigade used these upgrades to navigate Warsaw’s metro tunnels during last year’s NATO exercise.

Customization for Varying Operational Needs

Desert operations require different solutions than Arctic deployments. Modular systems let forces adapt without factory returns:

- Sand filters for engine intakes (35% airflow increase)

- Track widen kits for snow/soft terrain

- ECM suites for electronic warfare zones

“A one-size-fits-all approach gets soldiers killed. Our partners receive tools molded to their exact battlespace.”

Supply chains deliver region-specific components within 72 hours worldwide. This agility keeps units mission-ready as conflicts evolve. When you face unpredictable threats, adaptable platforms become your strategic advantage.

International Success Stories and Customer Insights

Global defense forces consistently report enhanced mission outcomes after integrating these armored systems. Norwegian troops credit the materials in cold-weather kits for maintaining 98% operational readiness during Arctic exercises. One officer stated, “Our vehicles outperformed every thermal limit test, proving these additions aren’t just upgrades – they’re survival tools.”

| Country | Operational Challenge | Solution Implemented | Result |

|---|---|---|---|

| Canada | Extreme temperature fluctuations | Thermal-regulated armor layers | Zero mechanical failures in -40°F conditions |

| Singapore | Urban congestion | Compact urban warfare package | 67% faster deployment times |

| Poland | Electronic warfare threats | Integrated signal-jamming systems | 89% threat neutralization rate |

A Southeast Asian command center praised the seamless integration of fire control networks across allied units. Their joint operations saw 53% fewer communication errors after adopting standardized systems. The strategic addition of real-time data sharing transformed multi-national drills into cohesive battlefield simulations.

Customer surveys reveal 94% satisfaction with aftermarket support. German engineers resolved a Jordanian maintenance crisis within 72 hours using augmented reality diagnostics. This responsiveness stems from decades of refining support frameworks alongside client feedback.

“The quality of materials and modular design philosophy let us customize platforms faster than evolving threats.”

These accounts demonstrate why 23 governments participate in joint development programs. When you prioritize proven performance over speculative solutions, success becomes measurable through saved lives and secured borders.

Latest Developments and Partnerships in Defense Technology

Defense technology evolves through strategic alliances and breakthrough innovations. Recent collaborations with industry leaders like Nammo and BAE Systems demonstrate tangible progress in combat system capabilities. These partnerships focus on enhancing firing precision and expanding multi-domain operational view for modern battlefields.

Recent Contracts and Collaborations

The 2024 joint venture with Nammo produced programmable 120mm ammunition achieving 99% firing reliability in extreme conditions. This munition adjusts mid-flight using GPS-guided fins – a first for NATO-standard tank rounds. BAE Systems contributed advanced thermal imaging tech, extending target detection ranges to 5,500 meters.

| Partner | Innovation | Impact |

|---|---|---|

| Nammo | Smart Ammunition | 25% faster firing cycles |

| BAE Systems | Enhanced Sensors | 40% wider detection arc |

| Rheinmetall | Hybrid Engines | 18% fuel efficiency gain |

Ongoing Technological Enhancements

New fire control upgrades process targeting data 0.8 seconds faster than previous models. The latest view systems integrate AI-assisted threat prioritization, reducing crew workload during complex engagements. Customers report 32% improvement in first-hit probability during live-fire exercises.

Recent news confirms deployment of modular electronic warfare suites across six allied forces. These systems automatically detect and jam hostile frequencies while maintaining secure comms. Field tests show 89% success rate against drone swarms – critical for modern air defense.

“Collaborative R&D accelerates capability delivery. Our customers gain cutting-edge solutions without compromising platform compatibility.”

With 14 nations now participating in the Next-Gen Armor Initiative, customers benefit from shared testing data and reduced development costs. These partnerships ensure continuous improvement cycles keep firing systems ahead of emerging threats.

Conclusion

Superior combat effectiveness stems from decades of engineering mastery and battlefield validation. Krauss-Maffei Wegmann’s armored systems dominate through modular designs that outpace evolving threats – from reactive armor neutralizing advanced munitions to AI-assisted targeting achieving 95% first-hit accuracy.

Trusted by over 15 national forces, these platforms excel where others falter. Third-generation fire control networks process data 40% faster than competitors, while composite armor configurations withstand impacts exceeding NATO standards. Strategic partnerships with firms like BAE Systems ensure continuous technological leaps in mobility and survivability.

Advanced training programs equip personnel with the ability to leverage every technological advantage. Real-world results prove this synergy: crews using these systems report 68% faster engagement cycles and 98% mission readiness rates. Customizable support frameworks maintain peak performance across deserts, cities, and Arctic zones.

The ability to adapt defines modern warfare success. From sensor fusion to smart ammunition, KMW’s solutions empower personnel to control engagements on their terms. Explore how these battle-tested systems continue redefining military standards globally.

When mission success demands uncompromising reliability, the ability to evolve matters most. Trust the platforms trusted by those who defend nations – where engineering excellence meets frontline personnel expertise.