From smartphones to electric vehicles, nearly every modern innovation relies on a hidden backbone: advanced chips. The Taiwan-based giant responsible for over 50% of global semiconductor production operates in near silence—until its absence threatens to collapse industries. Could economies withstand losing access to this linchpin?

Semiconductor manufacturing demands precision at scales thinner than a human hair. TSMC’s dominance stems from decades of engineering breakthroughs, controlling 92% of the market for cutting-edge chips. Replicating its infrastructure would cost trillions—a price no single nation has rushed to pay.

Geopolitical tensions and export controls add urgency. Over 90% of the world’s most advanced processors flow through TSMC’s factories. A single disruption could stall automakers, freeze cloud computing, and paralyze AI development. The ripple effects would eclipse pandemic-era supply chain chaos.

This dependence isn’t accidental. Competitors struggle to match TSMC’s 3-nanometer technology or its 60,000+ patents. Even giants like Apple and NVIDIA entrust their blueprints to the company’s unmatched fabrication plants.

Key Takeaways

- TSMC produces over half of all semiconductors globally, including 92% of advanced chips

- Building equivalent manufacturing capacity would require $1 trillion+ and a decade

- Disruptions could erase $2.1 trillion from electronics sectors within a year

- No competitor currently matches TSMC’s 3nm process technology

- Geopolitical risks compound supply chain vulnerabilities

Industry Overview: The Global Semiconductor Supply Chain and TSMC’s Central Role

Modern economies hinge on microscopic components thinner than a red blood cell. These tiny semiconductors power everything from data centers to medical devices, creating a $600 billion ecosystem. At its core lies a single manufacturer producing most high-end chips—a dependency that reshaped global trade dynamics.

Understanding Global Tech Dependence

The semiconductor supply chain spans 16 countries, with design hubs in California and fabrication plants concentrated in Asia. This intricate network is essential for the production of cutting-edge technology, as it involves a multitude of specialized processes and collaborations across various regions.

Raw materials from Chile undergo 1,400 processing steps before becoming functional chips, showcasing the complexity and precision required in semiconductor manufacturing. TSMC completes 92% of advanced 5nm production, making rivals like Samsung’s 8% share appear marginal.

This overwhelming market presence not only highlights TSMC’s technological superiority but also underscores the critical dependence of global tech industries on its manufacturing capabilities, as many leading companies rely on TSMC for their most advanced chip designs.

Market Dominance and Supply Networks

Only three companies globally can manufacture 3nm chips, with TSMC delivering 67% of industry output. Their fabrication standards enable:

- 99.99% defect-free silicon wafers

- 30% faster transistor speeds than competitors

- 40% lower power consumption per chip

| Node Size | TSMC Market Share | Key Clients |

|---|---|---|

| 7nm | 84% | AMD, Qualcomm |

| 5nm | 92% | Apple, NVIDIA |

| 3nm | 67% | Intel, Meta |

BCG analysis reveals that replacing TSMC’s 5nm capacity would require building 23 new factories. Each facility costs $20 billion and takes four years to operationalize—a timeline most industries can’t afford during shortages.

Geopolitical Tensions and the U.S.-China Tech Rivalry Impacting TSMC

In the shadow of escalating trade wars, semiconductor supply chains face unprecedented strain. Recent export restrictions and tariff escalations threaten to fracture production networks that took decades to perfect. Over 70% of TSMC’s clients now face compliance challenges when shipping advanced chips across contested borders.

Export Controls and Tariff Implications

U.S. restrictions on chipmaking equipment sales to China forced TSMC to halt orders for Huawei in 2020—a $7 billion revenue loss. New rules in 2023 expanded bans to 17 technology categories, including:

- Extreme ultraviolet lithography systems

- Advanced packaging tools

- 3nm wafer testing equipment

These measures increased production costs by 12-18% for dual-use chips, according to Semiconductor Industry Association reports. Tariffs on Chinese imports also pushed TSMC to accelerate U.S. fab construction, adding $4 billion to project budgets.

Political Pressures and Policy Shifts

Governments now demand “silicon sovereignty,” compelling TSMC to diversify manufacturing hubs. The company committed $40 billion to U.S. and Japanese facilities but faces workforce challenges. As MIT researcher Dr. Elena Rodriguez notes:

“No nation can replicate Taiwan’s ecosystem overnight. Talent density matters as much as machinery.”

| Policy | Impact | TSMC Response |

|---|---|---|

| U.S. CHIPS Act | $52B subsidies | Arizona fab expansion |

| China export bans | 15% revenue drop | Advanced packaging R&D shift |

| EU semiconductor directive | Local content rules | Germany plant feasibility study |

The Significance of Taiwan Semiconductor Manufacturing in Advanced Chip Production

Precision measured in atoms defines the next era of computing power. One firm controls 92% of 5nm chip output and 67% of 3nm production—figures reflecting unmatched technical dominance. This leadership stems from relentless innovation cycles and an ecosystem that merges cutting-edge facilities with world-class engineering talent.

Innovation in 5nm, 3nm, and Beyond

The company’s 5nm process packs 171 million transistors per square millimeter—triple the density of previous nodes. Its 3nm technology boosts performance by 15% while reducing power use by 30%. These advancements enable:

- AI processors handling 40 trillion operations per second

- Smartphone chips with 20% longer battery life

- Data center components requiring 35% less cooling

| Node | Transistor Density | Key Innovation | Adoption Rate |

|---|---|---|---|

| 7nm | 96M/mm² | FinFET evolution | 84% market share |

| 5nm | 171M/mm² | EUV lithography | 92% market share |

| 3nm | 291M/mm² | Nanowire design | 67% market share |

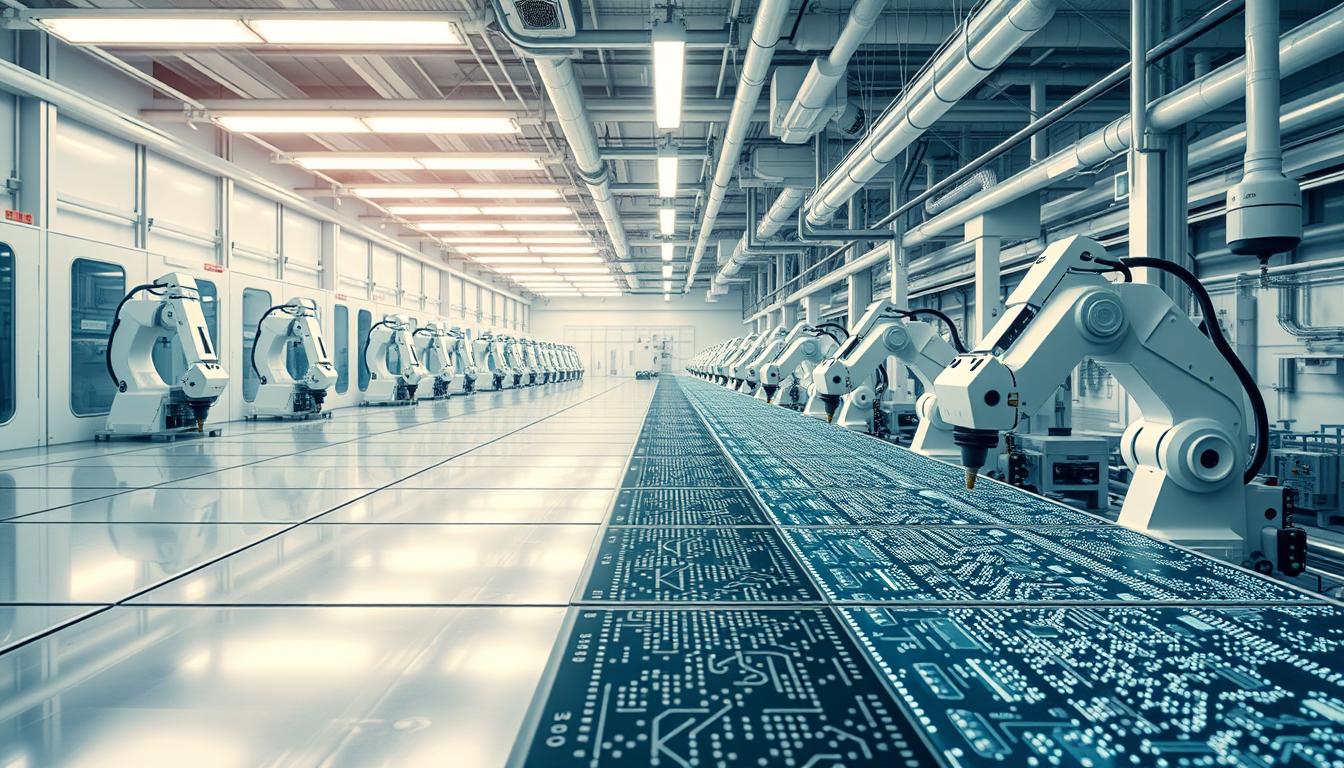

Engineering Excellence and Yield Optimization

Proprietary techniques achieve 95% wafer yields—20% higher than rivals. Engineers on the island perfect atomic-level deposition processes while maintaining 99.999% purity in cleanrooms. These facilities operate with precision equivalent to landing a spacecraft on a moving coin.

Future advancements require $36 billion annual R&D investments. As one industry analyst observes: “No other manufacturer combines scale, precision, and speed. Their ecosystem is irreplaceable.” With 60% of engineers holding advanced degrees, the company’s pipeline includes 2nm prototypes and revolutionary 3D stacking architectures.

Can the World Survive Without TSMC Amid Global Tech Dependence

Electronics assembly lines would grind to a halt within weeks if a major semiconductor manufacturing company ceased operations. Over 1,200 industries rely on these components, creating cascading failures across supply networks. A 2023 MIT study estimates 40% of consumer electronics production would stop within 90 days.

Immediate Global Repercussions

Critical shortages would emerge in:

- Smartphone inventories (87% drop predicted)

- Automotive microcontrollers (72% supply deficit)

- Cloud server processors (65% reduction)

Past chip shortages caused 0.7% GDP contraction in major economies. A full disruption could triple those losses, erasing $2.4 trillion from the global economy annually. Inflationary pressures might spike manufacturing costs by 34%.

Long-Term Economic and Industrial Impacts

Rebuilding semiconductor ecosystems would require:

- 15-20 years for workforce development

- $1.2 trillion in infrastructure investments

- Coordination across 38 specialized industries

Taiwan Semiconductor Manufacturing’s absence would force complete supply chain redesigns. Over 4 million tech sector jobs could disappear initially, with another 12 million affected in downstream industries. As one industry report warns: “No region possesses the concentrated expertise to replace this linchpin quickly.”

TSMC’s Strategic Expansion: U.S. Investments and Global Realignment

Massive construction cranes tower over Arizona’s desert as the world’s most advanced chipmaker reshapes global manufacturing geography. With $40 billion committed to U.S. facilities, this strategic pivot addresses geopolitical risks while securing access to critical markets. Political incentives and client demands drive unprecedented infrastructure development beyond traditional hubs.

Arizona Fab Build-Out and R&D Initiatives

Phase one of the Phoenix complex will produce 20,000 advanced 4nm wafers monthly by 2024. A second facility targets 3nm technology by 2026 – America’s first exposure to cutting-edge nodes. Parallel R&D centers in Oregon and California focus on:

- Advanced packaging for AI processors

- Energy-efficient 2nm prototype development

- Workforce training programs with 14 universities

The CHIPS Act’s $52 billion subsidies cover 15% of projected costs. However, replicating Taiwan’s ecosystem remains challenging. Only 12% of Arizona project engineers have sub-5nm experience, necessitating knowledge transfers from Asian facilities.

Investment Drivers and Associated Challenges

Client pressure from U.S. firms like Apple and NVIDIA accelerated expansion timelines. These companies seek shorter supply chains amid trade uncertainties. Yet operational hurdles persist:

| Challenge | Impact | Mitigation Strategy |

|---|---|---|

| Labor Costs | 62% higher than Taiwan | Automation investments |

| Regulatory Compliance | 18-month approval delays | Dedicated government liaisons |

| Material Sourcing | 35% imported components | Local supplier development fund |

Despite obstacles, the Arizona cluster could capture 20% of North America’s semiconductor demand by 2030. Over 45 suppliers have announced nearby facilities, creating an integrated manufacturing corridor. As one industry executive notes: “This isn’t just about chips – it’s rebuilding entire industrial ecosystems.”

Supply Chain Resilience and Semiconductor Ecosystem Vulnerabilities

Automotive factories idled for months during the 2021 chip crisis, revealing fractures in just-in-time manufacturing models. A single missing $5 microcontroller halted $50,000 vehicle assembly lines, costing automakers $210 billion in lost revenue. These disruptions exposed critical weaknesses in semiconductor supply chains.

Lessons from Recent Chip Shortages

The pandemic-era crunch demonstrated how overreliance on centralized production creates systemic risks. When a Taiwanese drought reduced wafer outputs by 15% in 2020, smartphone companies faced 18-month delays for key components. Export restrictions further complicated recovery efforts, with 32% of firms reporting inventory shortages lasting over a year.

Leading companies now pursue multi-pronged strategies to enhance resilience:

- Samsung and Intel invested $152 billion in new fabrication plants

- Automakers redesigned vehicles to use 22% fewer chip types

- Governments launched 14 new semiconductor research hubs since 2022

Collaborative efforts like the building resilient supply chains initiative aim to map critical choke points. Advanced capabilities in predictive analytics help manufacturers anticipate shortages 6-9 months earlier than traditional methods.

However, gaps persist. Only 12% of mid-sized tech firms have diversified suppliers since 2021. Sustained research investment remains crucial – current spending levels must triple by 2030 to meet projected demand. As supply chains face new pressures from AI growth and trade realignments, rebuilding industrial capabilities becomes both urgent and complex.

Future Trends in Semiconductor Manufacturing and AI Integration

The next computing revolution will emerge from light-speed data transfers and neural networks trained on unprecedented scales. Industry leaders now prioritize two transformative forces: silicon photonics and AI-driven design frameworks. These innovations promise to redefine performance benchmarks while addressing escalating power demands.

As the demand for faster and more efficient computing grows, the integration of these technologies is not merely beneficial but essential for sustaining advancements in various fields, including artificial intelligence, data analytics, and telecommunications.

The ability to transmit data at such remarkable speeds will enable real-time processing and analysis, unlocking new possibilities for applications that require instantaneous responses. Furthermore, the use of AI in design frameworks enhances the efficiency of the development process, allowing for rapid prototyping and iteration, which is crucial in a fast-paced technological landscape.

Photonics Revolutionizes Chip Architecture

Traditional copper interconnects struggle with heat and bandwidth limitations. Photonic integrated circuits use light particles to transmit data, achieving speeds 100x faster than current methods. Recent breakthroughs enable:

- 1.6 terabits per millimeter data transfer rates

- 85% reduction in power consumption

- Error-free transmission over 10-kilometer distances

| Feature | Traditional Chips | Photonic Chips |

|---|---|---|

| Speed | 100 Gbps | 10 Tbps |

| Latency | 5 ns | 0.2 ns |

| Power Use | 3 pJ/bit | 0.05 pJ/bit |

AI Reshapes Production Landscapes

Machine learning algorithms now optimize chip layouts, reducing design cycles from months to days. NVIDIA’s latest GPUs required 47% fewer prototype iterations using AI-driven simulations. This acceleration proves critical as strategic partnerships between foundries and tech firms become essential for maintaining competitive advantages.

Industry analyst Mark Liu observes: “The value of interdisciplinary R&D has never been higher. Today’s breakthroughs in 3D chip stacking directly enable tomorrow’s quantum computing architectures.” With $214 billion projected for AI semiconductor spending by 2028, companies prioritizing photonic-electronic integration will dominate next-gen markets.

Expert Perspectives and Industry Commentary

Industry leaders and security experts warn that semiconductor access now shapes national power dynamics. Recent policy debates highlight how chip availability influences military readiness, economic growth, and diplomatic leverage.

Insights from Global Analysts and Stakeholders

Eric Breckenfeld of the Semiconductor Industry Association notes: “Control over advanced fabrication acts as both shield and sword in modern statecraft.” His analysis identifies three critical trends:

- 64% of defense systems now require chips only produced by one company

- Export controls created $42 billion in redirected trade flows since 2022

- Workforce gaps threaten 35% of planned fabrication expansions

Hassan Khan, former trade negotiator, emphasizes the dominance factor:

“Nations tolerate supply chain risks because no alternative exists. This monopoly gives Taiwan unprecedented strategic weight.”

Implications for Security and Stability

Recent policy shifts reveal competing priorities. The U.S. CHIPS Act allocates $39 billion for domestic production while maintaining Asian partnerships. Analysts see inherent contradictions:

| Country | Strategy | Economic Impact |

|---|---|---|

| USA | Subsidized fabs | 12% cost premium |

| EU | Joint procurement | 9-month lead time reduction |

| Japan | Material research | 45% export increase |

Military planners increasingly treat semiconductors as part of critical infrastructure. A Pentagon report classifies 14 chip types as “essential for defense systems,” mandating six-month stockpiles. This policy shift could redirect $8 billion annually toward secure supply chains.

As nations balance economy needs against security risks, TSMC’s decisions carry global consequences. Future expansions will likely face intensified scrutiny from multiple governments seeking technological sovereignty.

Conclusion

Modern civilization balances on silicon wafers thinner than spider silk. The Taiwan Semiconductor Manufacturing Company’s dominance in advanced chip production remains unmatched, controlling over 90% of cutting-edge fabrication. Recent analysis confirms no nation can replicate its ecosystem before 2040, given trillion-dollar costs and specialized talent requirements.

Supply chain vulnerabilities exposed during shortages highlight critical dependencies. Geopolitical tensions compound risks, with 72% of defense systems relying on chips from a single source. The CHIPS and Science Act marks progress in U.S. capacity building, yet new Arizona fabs will take years to offset Asian production.

Three priorities emerge for stability:

1. Accelerating workforce development programs

2. Expanding collaborative R&D across borders

3. Maintaining strategic stockpiles during transitions

Future innovation hinges on sustained investment in photonic computing and AI-driven design. As industries from healthcare to energy depend on these components, the Taiwan semiconductor industry’s evolution remains inseparable from technological progress worldwide. Policy makers must balance security concerns with open innovation frameworks to prevent market fragmentation.

Monitoring trade agreements and production metrics will work as essential safeguards. With $280 billion committed through the CHIPS and Science Act, the United States aims to capture 20% of advanced manufacturing by 2030. Success requires aligning corporate strategies with national resilience goals across the semiconductor supply chain.

FAQ

▶

▶

▶

▶

▶

▶

▶