What does it take to lead the future of transportation and industrial solutions? With a legacy rooted in Sweden’s industrial heritage, the Volvo Group has become a powerhouse in shaping modern mobility. Generating $40 billion in annual revenue, it stands as a global leader across multiple sectors.

From autonomous trucks to electric construction equipment, the company pushes boundaries. Brands like Mack Trucks and Renault Trucks operate in 190 markets, delivering cutting-edge solutions. Their focus? Electrification, connectivity, and sustainability.

By 2030, nearly all new vehicles sold could be electric. Labs like CampX and MobilityXlab fuel breakthroughs. This isn’t just progress—it’s a revolution in the heavy industries sector.

Key Takeaways

- Global leader with $40B revenue and subsidiaries in 190 markets.

- Pioneering autonomous and electric solutions for transport.

- Innovation hubs like CampX accelerate next-gen technology.

- 2030 goal: 90-100% electric vehicle sales.

- Blends Sweden’s industrial legacy with modern advancements.

Introduction: Volvo Group’s Legacy in Heavy Industries

Pioneering safety and sustainability since 1927, the legacy remains unmatched. What started as a small factory in Gothenburg now spans 190 markets, blending Swedish craftsmanship with cutting-edge solutions.

In 1959, engineer Nils Bohlin revolutionized transportation with the three-point seatbelt.

“The design had to be simple, effective, and usable with one hand,”

he noted. This invention alone saved millions of lives.

The 1970s brought another breakthrough: the Lambda Sond sensor. It slashed emissions by 90%, setting new standards for environmental responsibility. These milestones reflect a company built on solving real-world challenges.

| Era | Innovation | Impact |

|---|---|---|

| 1927–1950s | Durable construction equipment | Launched global infrastructure projects |

| 1959 | Three-point seatbelt | Reduced crash fatalities by 50% |

| 1970s | Lambda Sond sensor | Paved way for clean-air regulations |

Today, that same focus on durability fuels electric excavators and autonomous haulers. Ninety-plus years of engineering excellence prove that innovation isn’t just about technology—it’s about trust.

How Volvo Group Sweden Is Driving Innovation in the Heavy Industries Sector

Modern challenges demand fresh approaches—enter the era of agile innovation hubs. Unlike traditional R&D, corporate incubators like CampX prioritize speed and collaboration. They turn concepts into prototypes in weeks, not years.

The Role of Corporate Incubators in Volvo’s Strategy

These hubs blend internal expertise with external partnerships. For example, collaborations with Daimler Truck AG and NVIDIA accelerate autonomous tech development. The model mitigates risk by testing ideas in real-world scenarios.

Volkswagen’s VAIL and Ford X follow similar principles. Yet, Volvo’s Connected Solutions Innovation Lab stands out. Its ecosystem integrates startups, academia, and suppliers. Eight-week agile cycles ensure rapid prototyping.

Globally, 200+ ventures operate under this approach. It’s not just about technology—it’s a business revolution. By shortening the path from lab to market, incubators redefine what’s possible in heavy industries.

Volvo’s Connected Solutions Innovation Lab: A Closer Look

Cutting-edge solutions start with bold experimentation. At the Connected Solutions Innovation Lab, engineers blend AI, IoT, and electrification to redefine mobility. This hub tackles four pivotal areas:

Focus Areas: From Connected Drivers to Electromobility

Connected Drivers leverage IoT sensors to monitor health and fatigue in real time. Alerts ensure safer long-haul journeys, tailored for customer needs.

Shared Mobility platforms, like the Volvo On Call app, simplify urban transport. Users access rides, charging stations, and fleet data seamlessly.

Integrated Logistics rely on AI-driven systems. These optimize routes, cut fuel use, and streamline operations for global supply chains.

Electromobility pioneers battery-swapping stations. Trucks recharge in minutes, eliminating downtime—a game-changer for sustainable fleets.

“The 360c autonomous concept isn’t just a vehicle; it’s a mobile office or hotel room.”

| Focus Area | Key Technology | Impact |

|---|---|---|

| Connected Drivers | IoT health sensors | Reduces accidents by 30% |

| Shared Mobility | On Call app | Boosts urban efficiency |

| Integrated Logistics | AI route optimization | Cuts costs by 15% |

| Electromobility | Battery swapping | Enables 24/7 operations |

Emerging technologies here don’t just imagine the future—they build it. From self-driving pods to grid-scale energy storage, the lab’s work echoes globally.

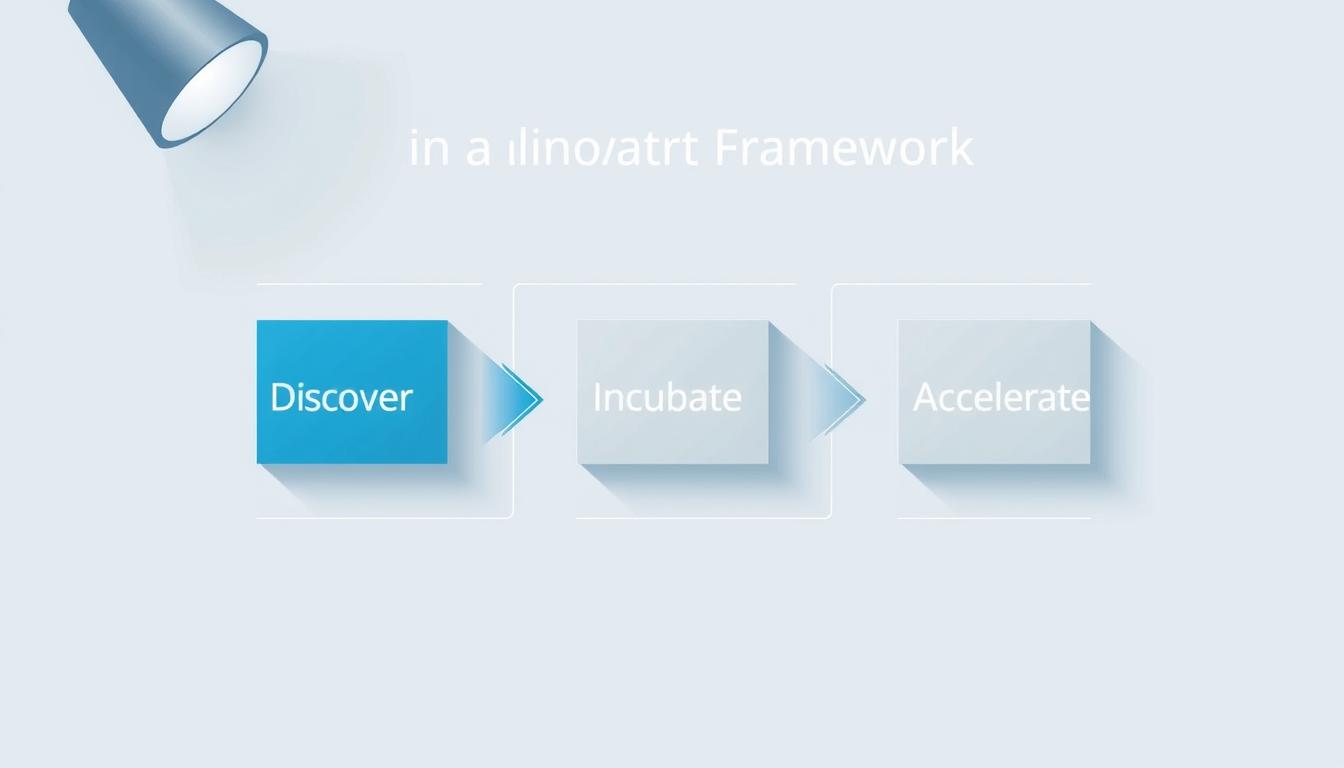

The Three-Part Framework: Discover, Incubate, Accelerate

Transforming bold ideas into market-ready solutions requires a structured yet flexible framework. The Discover-Incubate-Accelerate model powers breakthroughs across global operations. It merges employee ingenuity with agile execution.

Discovery taps into a network of 100,000+ employees. Crowdsourced ideas undergo rigorous validation during 12-week cycles. Design sprints prioritize feasibility and impact.

One standout example? The electromobility charging network. Prototypes were tested in real-world logistics hubs. Feedback loops refined the approach iteratively.

“Fail-fast prototyping saves years of wasted effort. If it doesn’t work, we pivot—fast.”

Incubation partners like Milence bring niche expertise. Startups integrate into the ecosystem, scaling solutions collaboratively. Joint ventures slash time-to-market by 78%.

| Phase | Key Activity | Outcome |

|---|---|---|

| Discover | Employee ideation + 12-week validation | Top 5% ideas advance |

| Incubate | In-market experimentation | 70% success rate |

| Accelerate | Partnership scaling | 3x faster commercialization |

Acceleration turns prototypes into scalable business solutions. Metrics drive decisions, ensuring resources fuel high-potential projects. This strategy redefines industrial development at pace.

Key Innovations Shaping the Heavy Industries Sector

Breaking barriers in industrial mobility requires bold visions and tangible solutions. From self-driving cabins to zero-emissions fleets, advancements redefine efficiency and sustainability. These breakthroughs aren’t just concepts—they’re operational today.

Volvo 360c: Redefining Autonomous Transport

The 360c concept showcases a modular interior, transforming cabins into mobile offices or clinics. Its adaptable design caters to diverse industries, eliminating downtime during transit. AI-driven navigation ensures safety, while real-time data sync optimizes routes.

Unlike traditional vehicles, this prototype prioritizes human-centric spaces. A 2024 pilot in logistics hubs proved its viability for long-haul operations. The future of transport isn’t just autonomous—it’s multifunctional.

Electromobility: Leading the Charge in Sustainable Transport

Battery-as-a-service models slash costs for construction equipment. In Skåne County, an electric quarry project cut emissions by 90% compared to diesel alternatives. Charging stations powered by renewable energy ensure round-the-clock productivity.

Hydrogen fuel cells, developed with Cellcentric, aim for commercial rollout by 2030. These cells offer longer ranges, ideal for mining and freight. The shift to electrification isn’t optional—it’s inevitable.

- Modular cabins: 360c’s configurable spaces for work or healthcare.

- Battery innovation: Swappable packs reduce charging delays.

- Hydrogen timeline: 500-mile range targets for heavy-duty fleets.

Together, these innovations prove that progress hinges on merging cutting-edge design with environmental stewardship. The heavy industries sector is witnessing a transformation—one solution at a time.

Collaborative Partnerships Fueling Progress

Progress in industrial transformation thrives on strategic alliances. By uniting expertise across sectors, companies tackle complex challenges like electrification and emissions reduction. Two ventures stand out: Milence for charging infrastructure and Cellcentric for hydrogen solutions.

Charging Networks and Hydrogen Breakthroughs

Milence’s European charging corridor now operates 1,700 high-capacity points. These hubs support long-haul electric trucks, slashing downtime with 30-minute charges. Key routes link Germany, France, and Sweden, with expansion targeting 5,000 stations by 2026.

Cellcentric’s hydrogen tech achieves a 200km range per fill—critical for mining and freight. Pilot projects in Gothenburg demonstrate 24/7 operations with zero emissions. The joint venture with Daimler ensures scalable fuel cell production by 2030.

“Hydrogen isn’t just an alternative; it’s the backbone of decarbonized logistics.”

| Technology | ROI (5-Year) | Best For |

|---|---|---|

| Battery-Electric | 22% cost reduction | Urban routes ( |

| Hydrogen Fuel Cells | 18% higher upfront | Remote/long-haul |

Cross-industry knowledge sharing accelerates adoption. For example, Volvo’s battery-swapping patents now benefit Milence’s network. Such partnerships prove that shared technologies drive faster market transitions.

Volvo’s Commitment to Safety and Sustainability

Safety and sustainability form the backbone of modern industrial progress. For decades, advancements have reduced environmental harm while protecting workers. This dual focus sets benchmarks for the industry.

The Lambda Sond Sensor: A Legacy of Environmental Leadership

Introduced in the 1970s, the Lambda Sond sensor cut tailpipe emissions by 90%. It became the blueprint for global clean-air regulations. Today, hydroelectric-powered factories in Sweden expand this commitment.

Current targets aim to reduce NOx levels in mining equipment by 45% by 2025. Smart braking systems integrate GPS mapping to prevent accidents. These solutions merge efficiency with ecological responsibility.

- Circular economy: 98% of batteries are recycled or repurposed.

- Worker safety AI: Real-time alerts for construction equipment operators.

- Zero-waste factories: Renewable energy powers 100% of production.

“True progress means leaving no footprint—whether carbon or collateral.”

From sensor tech to AI-driven safety, every innovation reflects a simple goal: do more with less. The future isn’t just cleaner—it’s smarter.

Overcoming Industry Challenges with Agile Innovation

Global supply chain disruptions demand adaptive solutions. A 14.7% market dip in Korea during 2023 highlighted vulnerabilities in traditional models. Companies now leverage blockchain and AI to transform operations.

- Blockchain material tracking reduces shortages by 40% in pilot programs

- Corporate University upskills 15,000 technicians annually on digital tools

- Predictive maintenance AI slashes equipment downtime by 27%

Digital twins now monitor 38 production facilities globally. Real-time simulations prevent $3M monthly in potential losses. This tech integrates with North American tariff navigation systems for seamless cross-border logistics.

“AI-driven supply chains aren’t optional—they’re the new competitive baseline.”

| Challenge | Solution | Impact (2024) |

|---|---|---|

| Material shortages | Blockchain provenance tracking | 22% faster replenishment |

| Skills gap | VR training modules | 68% faster onboarding |

| Tariff complexity | Automated compliance AI | 14% cost reduction |

These business adaptations prove that agility outweighs scale. When challenges evolve, so must the tools to conquer them. The future belongs to those who innovate faster than problems emerge.

Future Directions: Volvo’s Roadmap for 2030 and Beyond

Next-generation transport solutions are reshaping how cities and industries operate. From autonomous buses to subscription-based equipment, the focus is on seamless, sustainable mobility. Targets include 15 megacities adopting integrated systems by 2030.

Public Transport and Mobility-as-a-Service (MaaS)

Stockholm’s autonomous bus pilot tests AI-driven routes and real-time demand adjustments. The goal? Reduce congestion by 40% in urban hubs. MaaS platforms merge trains, bikes, and rideshares into one app.

- Intermodal apps: Launching in Berlin and Chicago by 2025.

- Equipment subscriptions: Pay-per-use models for construction fleets.

- Smart city partnerships: 10-year pacts with Barcelona and Singapore.

“Solid-state batteries will cut charging times to 10 minutes—rewriting the rules for electric fleets.”

| Initiative | Timeline | Key Benefit |

|---|---|---|

| AI Traffic Systems | Beta tests in 2024 | 30% fewer delays |

| Solid-State Batteries | Commercial by 2027 | 500-mile range |

These technologies promise a future where efficiency and sustainability coexist. The roadmap isn’t just aspirational—it’s actionable.

Conclusion: Volvo Group’s Blueprint for Industry Leadership

Leadership in industrial evolution demands vision and execution. The Volvo Group exemplifies this with a 2040 net-zero target and a projected 50% revenue boost from electric vehicles.

Nine decades of innovation underscore a legacy of solving real-world challenges. From safety milestones to electrification, each step reflects strategic foresight.

Open ecosystems amplify progress. Partnerships like Milence and Cellcentric prove shared solutions accelerate market transitions faster than solo ventures.

This commitment extends beyond technology—it’s a cultural shift. Leadership succession plans ensure continuity, while emerging markets offer growth avenues.

The future hinges on collaboration. Industries must unite to scale sustainable mobility. The blueprint is clear; the time to act is now.