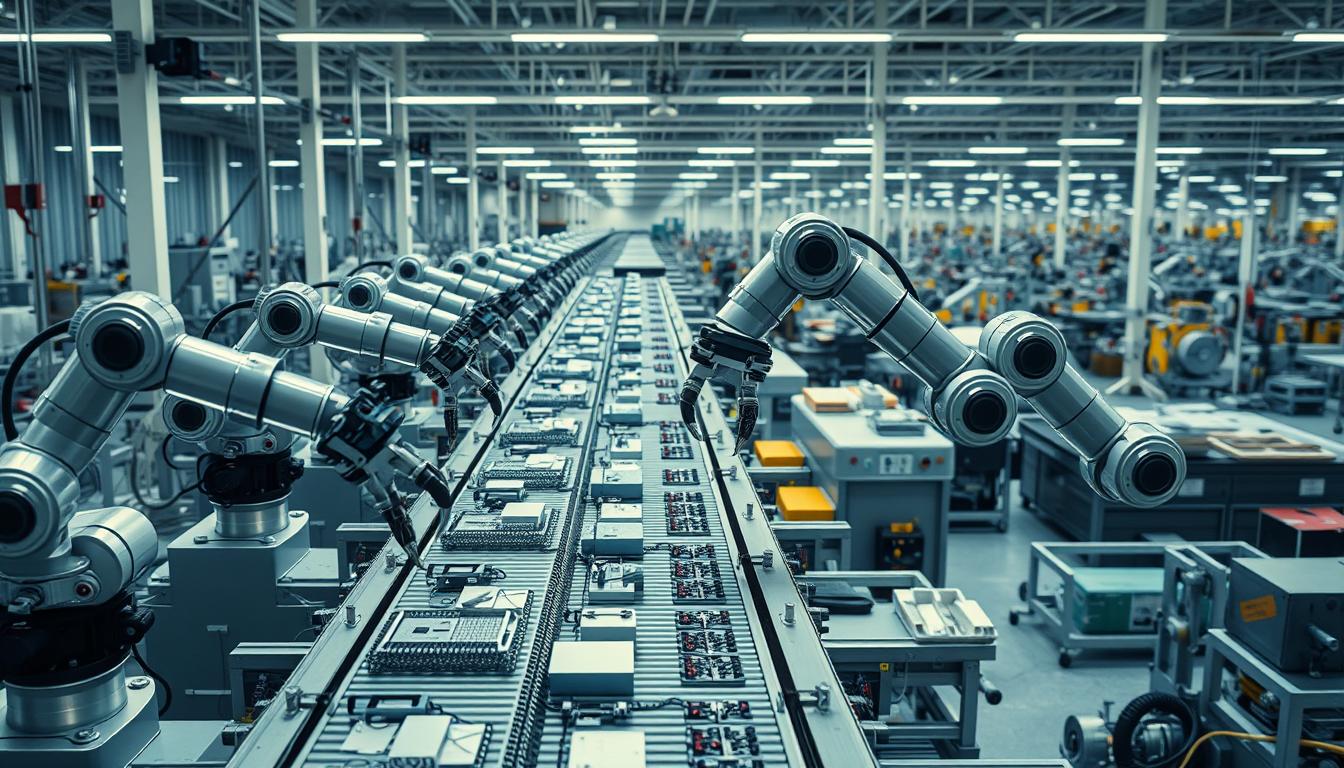

Imagine walking into a factory where machines adapt in real time, systems self-optimize, and robots collaborate seamlessly. This isn’t science fiction—it’s the reality of smart factories reshaping global manufacturing. These advanced facilities combine robotics, artificial intelligence, and interconnected data streams to redefine what’s possible on the production floor.

Traditional assembly lines are giving way to agile, data-driven operations. Sensors monitor every component, while algorithms predict maintenance needs before breakdowns occur. Collaborative robots now handle repetitive tasks, allowing human teams to focus on innovation. This shift isn’t just about speed—it’s creating safer workplaces and reducing errors by 45% in some sectors.

The backbone of this revolution? Integrated data systems that connect machines across entire factory networks. From raw material tracking to final quality checks, digital threads ensure precision at every stage. Major automotive companies already use these technologies to reconfigure production lines in hours rather than weeks.

Key Takeaways

- Smart factories use automation to boost efficiency and flexibility

- Real-time data analysis prevents downtime and improves decision-making

- Collaborative robots enhance safety while working alongside humans

- Digital integration allows rapid adaptation to market changes

- Industry 4.0 technologies reduce waste and energy consumption

The Evolution of Robotics and Smart Factories

Over two centuries, production hubs transformed from manual workshops to data-driven ecosystems. Early manufacturing relied on human labor and mechanical tools. Today, intelligent systems manage entire workflows with minimal oversight.

From Traditional Manufacturing to Industry 4.0

The first industrial revolution introduced steam power. The third brought computers to factories. Now, Industry 4.0 merges physical operations with digital twins and real-time analytics. This shift enables machines to communicate, self-diagnose errors, and optimize processes autonomously.

Milestones in the Development of Smart Factories

Three breakthroughs accelerated this transformation. Artificial intelligence enabled predictive maintenance, cutting downtime by 30% in automotive plants. Connected sensors (internet things) created visibility across supply chains. Finally, big data analysis helped companies reduce material waste by 22% annually.

Modern robots handle complex tasks like precision welding and micro-assembly. They’ve reduced repetitive tasks for workers by 60% since 2010. These technologies form the backbone of adaptable production systems, proving innovation drives industrial progress.

How Robots and Smart Factories Are Changing Industry Rules

Advanced robotics now deliver microscopic accuracy across assembly lines. Integrated sensor networks scan components 500 times per second, catching defects invisible to human eyes. This shift elevates product consistency while slashing error rates by up to 58% in electronics manufacturing.

Revolutionizing Quality Assurance

Automated inspection systems combine visual sensors with machine learning algorithms. These tools identify hairline fractures in metal castings and microscopic flaws in circuit boards. Real-time feedback loops adjust processes mid-operation, preventing batch failures before they occur.

Collaborative robots handle delicate tasks like pharmaceutical packaging with zero contamination risk. Human technicians now oversee multiple automation stations simultaneously, combining human oversight with robotic precision. This partnership reduces workplace injuries by 37% in heavy machinery plants.

- AI-powered vision systems achieve 99.98% defect detection accuracy

- Self-calibrating machines maintain tolerances within 0.002 millimeters

- Predictive analytics cut material waste by 19% through process optimization

Intelligent control systems now adapt to supply chain fluctuations automatically. When sensor data indicates raw material variations, robots recalibrate tooling pressures within seconds. This responsiveness keeps productivity stable despite external disruptions.

Technological Pillars Driving Industry Change

Modern industrial transformation thrives on interconnected digital frameworks. Four core innovations form the backbone of this shift, enabling unprecedented precision and adaptability in production environments.

Artificial Intelligence, Machine Learning, and Big Data

Artificial intelligence analyzes equipment vibrations to predict bearing failures 72 hours before breakdowns. Machine learning algorithms optimize energy consumption patterns, reducing factory power usage by 18% annually. “Data-driven insights now guide decisions that previously relied on human intuition,” notes a leading automation engineer.

Big data systems process millions of sensor readings daily, identifying hidden correlations between material quality and output consistency. This approach slashes defect rates while maintaining 99.4% equipment uptime across automotive plants.

Internet of Things (IoT) and Edge Computing

Smart sensors enable real-time communication between assembly stations and inventory systems. Edge computing devices process quality checks locally, cutting latency by 83% compared to cloud-based alternatives. This connectivity allows immediate adjustments when temperature fluctuations affect chemical mixtures.

Collaborative Robotics and Mobile Automation

Third-generation robotics now feature force-sensitive grippers for handling fragile components. Mobile platforms transport materials between workstations while avoiding obstacles using LiDAR mapping. These systems reduce manual lifting injuries by 41% in electronics assembly lines.

- AI models recalibrate welding robots based on metal thickness variations

- IoT-enabled predictive maintenance saves $3.7M annually per large factory

- Collaborative arms perform 92% of repetitive packaging tasks

Revolutionizing Production Processes and Workforce Dynamics

Automation reshapes factory floors by eliminating bottlenecks in manufacturing workflows. Intelligent systems now handle 73% of repetitive tasks like material sorting and component assembly, freeing human teams for complex problem-solving. This shift boosts efficiency while reducing error-prone manual interventions.

Enhancing Efficiency and Reducing Repetitive Tasks

Automated guided vehicles transport materials 40% faster than manual carts in electronics plants. Vision-equipped robots perform quality checks during production, cutting inspection times by 65%. These processes enable companies like Ford to reconfigure assembly lines in 8 hours instead of 3 days.

Real-time monitoring tools slash downtime by predicting equipment failures. A major appliance manufacturer reduced maintenance costs by $1.2 million annually through predictive analytics. Such innovations let workers focus on optimizing workflows rather than routine machine oversight.

Shifting Human Roles in Automated Environments

Technicians now oversee multiple automation stations while analyzing performance data. BMW retrained 12,000 employees for roles in robotics programming and system optimization. This transition creates safer workplaces while increasing output per shift by 19%.

- AI-driven scheduling reduces material waste by 24% in chemical plants

- Collaborative robots handle 83% of packaging tasks in food processing

- Workforce training programs increased technician salaries by 22%

Forward-thinking companies combine human creativity with machine precision. The result? Faster innovation cycles and manufacturing systems that adapt to market shifts within hours.

Real-Time Data and Process Optimization in Smart Factories

Modern production lines thrive on instant insights. Over 12,000 sensors in a single automotive plant now track vibrations, temperatures, and energy use. This data flows through integrated networks, enabling machines to self-adjust tolerances during process execution.

Connectivity and Predictive Maintenance

Interconnected systems flag anomalies before failures occur. A leading tire manufacturer reduced unplanned downtime by 52% using vibration data from IoT-enabled mixers. Algorithms cross-reference historical patterns with live inputs, triggering maintenance alerts when wear exceeds safe thresholds.

Continuous monitoring slashes repair costs. Chemical plants using real-time data analysis report 34% fewer pump replacements. “We fix issues during scheduled pauses instead of halting production,” explains a plant supervisor. This approach keeps annual output consistent while extending equipment lifespan.

| Metric | Before Optimization | After Implementation |

|---|---|---|

| Defect Detection Rate | 88% | 99.6% |

| Maintenance Costs | $2.1M/year | $1.4M/year |

| Energy Consumption | 18.4 kWh/unit | 14.9 kWh/unit |

Enhanced connectivity allows rapid response to supply chain shifts. When a semiconductor factory detected resin impurities, data-driven adjustments compensated within minutes. This agility prevents waste while maintaining strict quality standards across global operations.

Overcoming Supply Chain Challenges with Advanced Manufacturing

Global supply networks face unprecedented pressures from material shortages and shifting consumer needs. Advanced manufacturing practices now provide robust solutions through digital integration and predictive modeling.

Streamlining Operations Through Digital Tools

Digital twins create virtual replicas of physical supply chains, enabling manufacturers to simulate disruptions and optimize routes. A leading aerospace company reduced inventory costs by 28% using this technology to predict component demand. Real-time tracking systems update stock levels automatically, preventing overproduction of slow-moving items.

Integrated platforms connect suppliers with production facilities through manufacturing supply chains. This visibility helps companies redirect shipments within hours when port delays occur. “We now adjust procurement strategies before shortages impact production,” shares a logistics manager at a major automotive firm.

Meeting Evolving Consumer Needs

Flexible production systems enable rapid shifts between product variants. When a home appliance maker noticed rising demand for energy-efficient models, their smart factories reconfigured assembly lines in 14 hours. Key strategies include:

- AI-driven demand forecasting with 94% accuracy rates

- Modular equipment designs for quick retooling

- Supplier performance analytics to mitigate risks

These approaches help the manufacturing industry maintain 98% on-time delivery rates despite market volatility. By aligning resources with real-time insights, companies build resilience while meeting tight delivery windows.

Conclusion

The manufacturing landscape now operates at the intersection of precision and adaptability. By integrating artificial intelligence and IoT networks, smart factories achieve unprecedented levels of efficiency while maintaining rigorous quality control standards. Real-time data streams enable predictive maintenance strategies, reducing downtime by over 50% in leading automotive plants.

Digital twin technology allows manufacturers to simulate processes before implementation, minimizing resource waste. These advancements prove transformative across supply chains and workforce dynamics. Collaborative robots handle delicate tasks with sub-millimeter accuracy, while human teams focus on system optimization and innovation.

The journey toward fully connected production systems continues accelerating. As new technologies emerge, they reinforce manufacturing’s shift toward responsive, sustainable operations that meet evolving market demands without compromising output quality. This analysis focuses strictly on technological progress, avoiding discussions of financial tools to maintain clear industrial relevance.