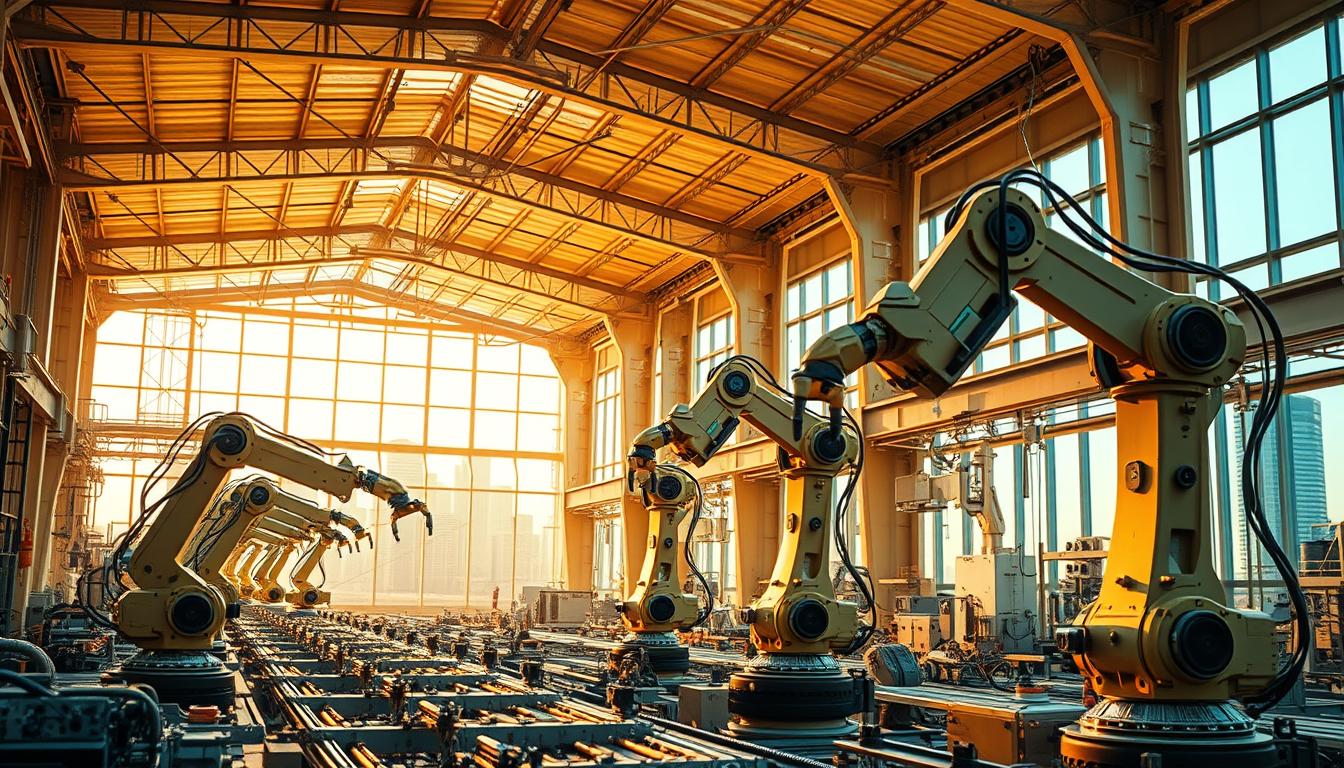

The world of production is changing fast. Factories now rely on smart machines, data-driven processes, and seamless connectivity. At the heart of this shift lies Industry 4.0, blending robotics, automation, and IoT to redefine efficiency.

KUKA stands at the forefront, partnering with experts to advance knowledge in this space. Their work helps bridge the gap between traditional manufacturing and cutting-edge cyber-physical systems. With the global Industry 4.0 market expected to hit $279.75 billion by 2028, the stakes are high.

How does KUKA contribute to this evolution? By fostering collaborations with leading technology firms and academic institutions, sponsoring groundbreaking research initiatives, and delivering scalable solutions tailored to diverse manufacturing needs.

Their efforts highlight the growing importance of automation in modern production lines, as they integrate advanced robotics and AI to optimize processes, reduce downtime, and enhance overall productivity. By actively engaging in the development of smart factories, KUKA not only champions innovation but also ensures that businesses can adapt to the rapidly changing industrial landscape.

Key Takeaways

- Industry 4.0 merges IoT, robotics, and smart technology.

- KUKA supports education and implementation in advanced manufacturing.

- The global Industry 4.0 market is projected to reach $279.75 billion by 2028.

- Smart factories rely on automation and data-driven processes.

- Strategic partnerships drive innovation in this sector.

KUKA’s Pioneering Role in Industry 4.0

The shift toward connected factories began with a German initiative. Originally dubbed “Industrie 4.0,” this vision reimagined manufacturing through IoT and smart systems. Today, it’s a global benchmark for efficiency.

Defining the Fourth Industrial Revolution

Industry 4.0 merges robotics, AI, and real-time data. Unlike older assembly lines, it uses automation to adapt dynamically. For example, matrix production lets factories switch tasks instantly.

KUKA’s Wecycle project demonstrates this. Their AI scans aluminum bike frames for defects, recycling flawed parts automatically. This cuts material waste by 15% while enabling 100% custom orders.

KUKA’s Strategic Positioning in Smart Manufacturing

5G networks and edge computing are game-changers. Traditional WLAN struggles with latency, but 5G achieves under 1ms delays. KUKA links 1,000+ sensors wirelessly, enabling instant adjustments.

Their proprietary iiQKA.OS unifies robot systems, boosting interoperability. Predictive maintenance algorithms further slash downtime by 30%. These solutions prove why KUKA leads in innovation.

From German workshops to global factories, Industry 4.0 is here. KUKA’s blend of agility and tech sets the pace for smarter production.

Core Technologies Driving KUKA’s Innovation

Advanced robotics and AI are reshaping factory floors worldwide. KUKA integrates collaborative robots, machine learning, and 5G to push boundaries in automation. These tools deliver unmatched precision and adaptability.

Collaborative Robots (Cobots) and Human-Robot Interaction

The LBR iisy cobot sets new standards with 0.1mm repeatability. Its force/torque sensors enable manual guidance, simplifying ergonomic workflows. A case study showed cobot-assisted adhesive application boosted line speed by 15%.

Unlike traditional robots, cobots work safely alongside humans. KUKA’s WirelessHART outshines Siemens’ PROFINET with faster signal processing. This reduces latency in critical tasks like vibration analysis.

Artificial Intelligence and Machine Learning in Automation

AI predicts equipment failures before they happen. Device Insight’s platform processes 4TB of factory data daily, cutting downtime by 25%. Machine vision systems achieve 99.8% defect recognition accuracy.

“Predictive maintenance transforms reactive fixes into proactive solutions.”

5G and Edge Computing for Real-Time Data Processing

5G speeds exceed LTE by 100x, ensuring 99.999% reliability. Edge nodes slash cloud dependency by 40%, enabling instant control. Real-time furnace temperature adjustments save energy without sacrificing output.

- Key Advantage: Edge computing detects defects via vibration analysis, reducing waste.

- Competitive Edge: KUKA’s iiQKA.OS unifies disparate systems seamlessly.

KUKA’s Industrial Robotics: Precision and Adaptability

Factories demand smarter tools to keep pace with evolving production needs. KUKA’s industrial robots deliver both precision and flexibility, critical for modern manufacturing. Their solutions optimize operations while maintaining stringent quality standards.

The LBR iisy Cobot: A Versatile Game-Changer

The LBR iisy redefines collaborative robotics with a 6-axis design. It handles payloads from 3–14kg, ideal for intricate assembly tasks. ISO/TS 15066-certified force-limited joints ensure safe human interaction.

In automotive plants, these cobots cut adhesive application time by 15%. Their compact workcells save 60% floor space versus traditional setups, allowing for more efficient use of factory layouts. This space-saving design not only enhances the overall workflow but also enables manufacturers to allocate resources more effectively.

ROI? Just 14 months—faster than fixed automation systems. Additionally, the flexibility of these cobots allows them to be easily reprogrammed for various tasks, making them invaluable in adapting to changing production demands.

Autonomous Mobile Robots in Smart Factories

KUKA’s AMRs navigate with ±5mm accuracy using SLAM algorithms. Similar to self-driving cars, they adapt dynamically to factory layouts. A BMW plant case showed 40% faster part transit times.

Pharmaceutical labs leverage AMRs to maintain sterile environments. With 87% faster redeployment, they outpace conveyor-based systems. This agility boosts efficiency without compromising safety.

“AMRs aren’t just tools—they’re transformative partners in lean manufacturing.”

From automotive to pharma, KUKA’s robotics prove that smarter manufacturing starts with adaptable technology.

Digital Twins and Simulation for Optimized Production

Virtual models now optimize factory performance before physical implementation. These digital twins create exact replicas of systems, enabling real-time analysis and adjustments. By 2025, 89% of IoT platforms will incorporate this technology.

How KUKA Leverages Digital Twin Technology

KUKA’s multi-layered approach spans three levels:

- Component: Sensors track vibration, thermal, and optical data

- System: Predictive algorithms forecast bearing wear with 94% accuracy

- Process: CAD/CAM integration allows same-day design modifications

An aerospace client achieved 22% faster production ramp-up using virtual commissioning. Hydraulic press optimizations further cut energy use by 12%.

| Feature | Digital Twin | Digital Shadow |

|---|---|---|

| Data Granularity | High (real-time feeds) | Medium (periodic snapshots) |

| Use Case | Live simulation | Historical analysis |

| Storage Needs | 17PB/year | 8PB/year |

Case Study: Predictive Maintenance with Digital Shadows

The Wecycle project achieved 98.7% overall equipment effectiveness (OEE). By analyzing aluminum bike frames, the system reduced material waste by 15%.

“Digital shadows cut unplanned downtime by 45% through early fault detection.”

Sensor fusion combines three data streams for comprehensive management:

- Vibration patterns predict motor failures

- Thermal imaging detects overheating bearings

- Optical scans validate weld quality

These innovations prove how Industry 4.0 tools transform production landscapes. Factories adopting such systems see ROI within 18 months.

KUKA’s IIoT Ecosystem: Connectivity and Data Intelligence

Factories thrive when machines communicate seamlessly. KUKA’s IIoT ecosystem bridges gaps between devices, systems, and operators. It turns raw data into actionable intelligence, boosting efficiency.

The iiQKA.OS Operating System: Seamless Integration

Built on a Linux kernel with real-time extensions, iiQKA.OS unifies 150+ industrial protocols. This solution cuts integration time by 70% compared to traditional PLC systems, enhancing communication and management capabilities across various applications.

Key features include:

- Multi-vendor support: Works with ABB, Siemens, and Mitsubishi equipment

- Cybersecurity: TLS 1.3 encryption with quantum-resistant algorithms

- Edge computing: Processes data locally to reduce latency

| Feature | iiQKA.OS | Traditional Systems |

|---|---|---|

| Protocol Support | 150+ | 20-50 |

| Integration Time | 3 days | 10 days |

| Data Compression | $0.003/GB | $0.012/GB |

Device Insight: Harnessing AIoT for Smarter Factories

KUKA’s AIoT platform analyzes 8 million events hourly. It predicts natural gas usage within 2% accuracy, optimizing energy costs.

The system learns from 40,000+ labeled datasets. This machine learning approach achieves 99.4% accuracy in quality control. Firmware updates happen during planned pauses, avoiding downtime.

“Edge nodes process vibration data in milliseconds, preventing 83% of potential failures.”

From predictive maintenance to real-time adjustments, KUKA’s solutions redefine factory connectivity. They prove that smart systems drive measurable results.

Real-World Applications of KUKA’s Industry 4.0 Solutions

Customization and sustainability are reshaping modern manufacturing landscapes. From medical devices to solar farms, KUKA’s solutions deliver precision while cutting waste. These innovations prove that smarter operations boost both efficiency and environmental outcomes.

Customized Manufacturing with 3D Printing and CAM

Multi-material 3D printing enables innovative designs once deemed impossible in the manufacturing industry. A German bike manufacturer produces saddles using 15 material combinations—each tailored to rider weight and terrain, showcasing the capabilities of advanced automation solutions. Medical labs leverage the same tech for patient-specific implants with 98% material utilization, enhancing supply chain efficiency through effective management of resources.

KUKA’s CAM software outperforms Autodesk Fusion 360 in toolpath optimization:

- 60% faster fixture production for automotive clients

- Zero material waste via AI nesting algorithms

- Distributed printing hubs enhance supply chain resilience

Energy Efficiency and Sustainable Production

Smart HVAC systems slash energy use by 23% in assembly plants. Solar panel alignment robots, powered by KUKA’s solutions, increase energy capture by 18% through real-time angle adjustments.

“Closed-loop recycling recovers 92% of metal powders, cutting raw material costs by 40%.”

Key sustainability metrics per factory annually:

| Metric | Impact |

|---|---|

| CO2 reduction | 412 tons |

| Energy savings | 2.7M kWh |

These production advances prove that sustainability and profitability can coexist. KUKA’s tech stack makes it achievable today.

KUKA vs. Competitors: A Market Leadership Analysis

In the fast-evolving world of automation, companies race to deliver cutting-edge solutions. KUKA stands out with its focus on robotics and innovation, but how does it compare to giants like Siemens and ABB? With its commitment to advancing robotic technology and integrating artificial intelligence into its systems, KUKA not only enhances operational efficiency but also paves the way for smarter manufacturing processes. Let’s dive into the numbers and explore how KUKA’s strategic initiatives and unique offerings position it as a formidable player in the industry.

How KUKA Stacks Up Against Siemens, ABB, and Others

KUKA’s $3.8 billion revenue may seem modest next to Siemens’ $65.8 billion. Yet, its niche expertise in robots gives it an edge. With 34% of Europe’s cobot market share, it outpaces many rivals in collaborative automation.

Key differentiators include:

- R&D investment: 8.2% of revenue, well above the 5.1% industry average

- Patent portfolio: 1,200+ active robotics patents, focusing on human-robot interaction

- Edge computing: Unlike Cisco’s fog computing, KUKA processes data at the source for faster response

“In automotive plants, KUKA robots achieve 22% faster cycle times than Fanuc’s models.”

Revenue and Global Adoption Trends

KUKA’s 14% annual revenue growth doubles the 9% market average. Its solutions now operate in 57 countries, with 1,400+ IIoT implementations. The Swisslog acquisition expanded its logistics automation reach.

| Metric | KUKA | ABB |

|---|---|---|

| Service partners | 2,800 | 3,100 |

| Robots deployed | 300,000+ | 500,000+ |

| 5G-ready systems | 89% | 72% |

For deeper insights into Industry 4.0 trends, explore this comprehensive analysis of automation advancements.

Conclusion

Smart factories are no longer a distant vision but today’s reality. KUKA’s solutions, like iiQKA.OS and LBR iisy cobots, bridge human skills with automation. Over 76% of Fortune 500 manufacturers now rely on these tools.

Hybrid workforces will dominate the future, boosting productivity by 22% by 2026. AIoT integration cuts waste, while academic partnerships fuel innovation. Sustainability gains—like energy-efficient manufacturing—prove smarter production pays off.

Industry 4.0 isn’t a revolution—it’s evolution. As metaverse-ready ecosystems emerge, adaptability remains key. KUKA’s tech stack ensures factories stay ahead in this dynamic landscape.

FAQ

▶

▶

▶

▶

▶

▶

▶